Tired of dealing with monument suppliers who cause delays or deliver subpar work? Unreliable partners create stress, upset families, and ultimately damage your funeral home's reputation. Finding the right manufacturer is crucial.

Finding a reliable gravestone manufacturer means doing your research. Check their reputation, ask for references, review their work samples, understand their production process, and insist on clear contracts outlining quality standards and warranties. Good communication is also essential.

Choosing a monument supplier isn't just about price. It's about trust and ensuring the final tribute for a family is perfect. I learned this firsthand, first working in a factory and later sourcing memorials globally for my trading company. A bad supplier can cause endless headaches for funeral directors like Sarah, impacting everything from schedules to client satisfaction. Let's explore how you can partner with manufacturers you can truly depend on, starting with the often-tricky subject of cost.

How Much Does a Grave Marker Cost?

Wondering about the cost of memorials makes budgeting hard, right? Unexpected prices can strain finances or lead to difficult conversations with families. Knowing the factors involved helps you manage expectations and costs effectively.

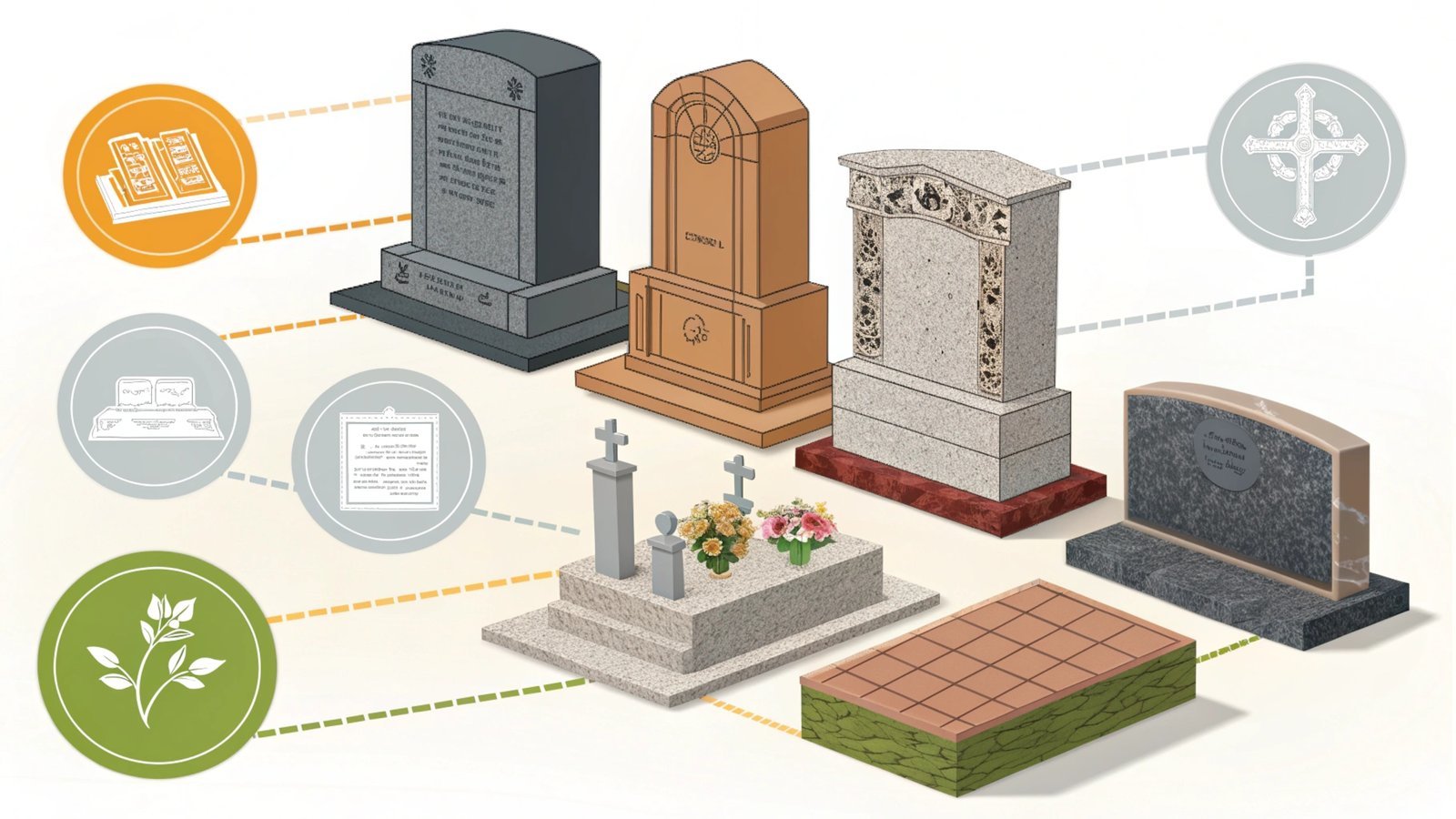

Gravestone costs1 vary widely based on material (granite grade, color), size, shape complexity, design intricacy (carving, etching), finish, lettering amount, and the manufacturer's location or type (direct manufacturer vs. retailer). There is no single fixed price.

When I first started sourcing monuments, I was surprised by the price variations. It's not arbitrary; specific factors drive the cost. Understanding these helps you explain pricing to families and negotiate better with suppliers.

Key Cost Factors2:

- Material: The type of stone is a major driver. Granite is common, but its price varies by color, rarity, and grade (quality). Common grey granite is usually less expensive than unique colors like blue pearl or reds. Marble is often more expensive and less durable outdoors in many climates. Bronze is another option, usually priced by weight and complexity.

- Size and Weight: Larger, thicker stones require more raw material and are harder to handle, increasing cost.

- Shape and Complexity: A simple rectangular marker costs less than a custom shape with curves, multiple pieces, or intricate cuts.

- Design and Finish: Hand carving, detailed laser etching (like shadow carving), polished surfaces (more polishing steps = higher cost), and added elements like porcelain photos increase labor and price. Sandblasting lettering is standard, but complex fonts or extensive text add up.

- Supplier Type & Location3: Buying directly from a large manufacturer, especially overseas like in China, might offer lower base prices due to scale and labor costs. However, you must factor in shipping, import duties, and potential communication challenges. Buying from a local monument retailer often includes design services and installation but at a higher price point.

Here's a simplified breakdown:

| Cost Factor | Lower Cost Examples | Higher Cost Examples | Why? |

|---|---|---|---|

| Material | Standard Grey Granite | Rare Colors (Blue Pearl), Marble, Bronze | Material rarity, difficulty sourcing |

| Size | Small flat marker | Large upright monument, Mausoleum | Amount of material, handling difficulty |

| Shape | Simple rectangle | Custom shapes, statues | Design/cutting complexity |

| Design/Finish | Standard sandblast, basic polish | Hand carving, shadow etch, full polish | Labor intensity, specialized skills |

| Supplier | Overseas Manufacturer (base price) | Local Full-Service Retailer | Added services, overheads, shipping |

Always get detailed quotes breaking down these elements.

What is a Headstone Maker Called?

Unsure what term to use when searching for suppliers? Using the wrong words can lead you down confusing paths online or make conversations with industry peers unclear. Knowing the right terms helps communication.

A headstone maker can be called a manufacturer, monument builder, monument dealer, retailer, or sometimes a memorialist. The specific term often depends on their role in the supply chain, from quarrying and production to sales and installation.

In the funeral industry, we sometimes use terms interchangeably, but there are differences. When I was running my trading company, knowing who did what was essential for sourcing effectively. It matters for you too, especially when assessing reliability and capability.

Understanding the Roles:

- Manufacturer: This term usually refers to the factory that actually quarries the stone (or buys blocks) and processes it into finished or semi-finished monuments. They cut, shape, and polish the stone. Many large manufacturers, like those I worked with extensively in China's Fujian province, operate on a large scale, often supplying wholesalers or retailers rather than directly selling to the public or individual funeral homes.

- Monument Builder / Monument Dealer / Retailer: These businesses typically buy finished or blank stones from manufacturers or wholesalers. They then work directly with families or funeral homes on design, lettering (sandblasting, etching), and installation. They are often the local face families interact with. Sarah, at Johnson Family Funeral Home, likely works with one or more of these local businesses.

- Memorialist: This is a broader term, often used for someone skilled in the art and craft of creating memorials, encompassing design and sometimes carving or lettering.

- Engraver / Etcher: These are specialists focused solely on adding the inscriptions and designs to the stone surface, sometimes working as subcontractors for retailers.

So, when you're looking for a "maker," you need to decide if you want to connect directly with a large-scale manufacturer (often involving importing and logistics) or work with a local monument builder/retailer who handles the final stages and installation. Both can be reliable, but their services and pricing structures differ. Knowing these terms helps you clarify who you are dealing with.

Where Are Most Headstones Made?

Do you know where the memorials you offer families actually come from? Not knowing the origin can leave you unaware of potential quality variations, supply chain risks, or cost implications linked to location.

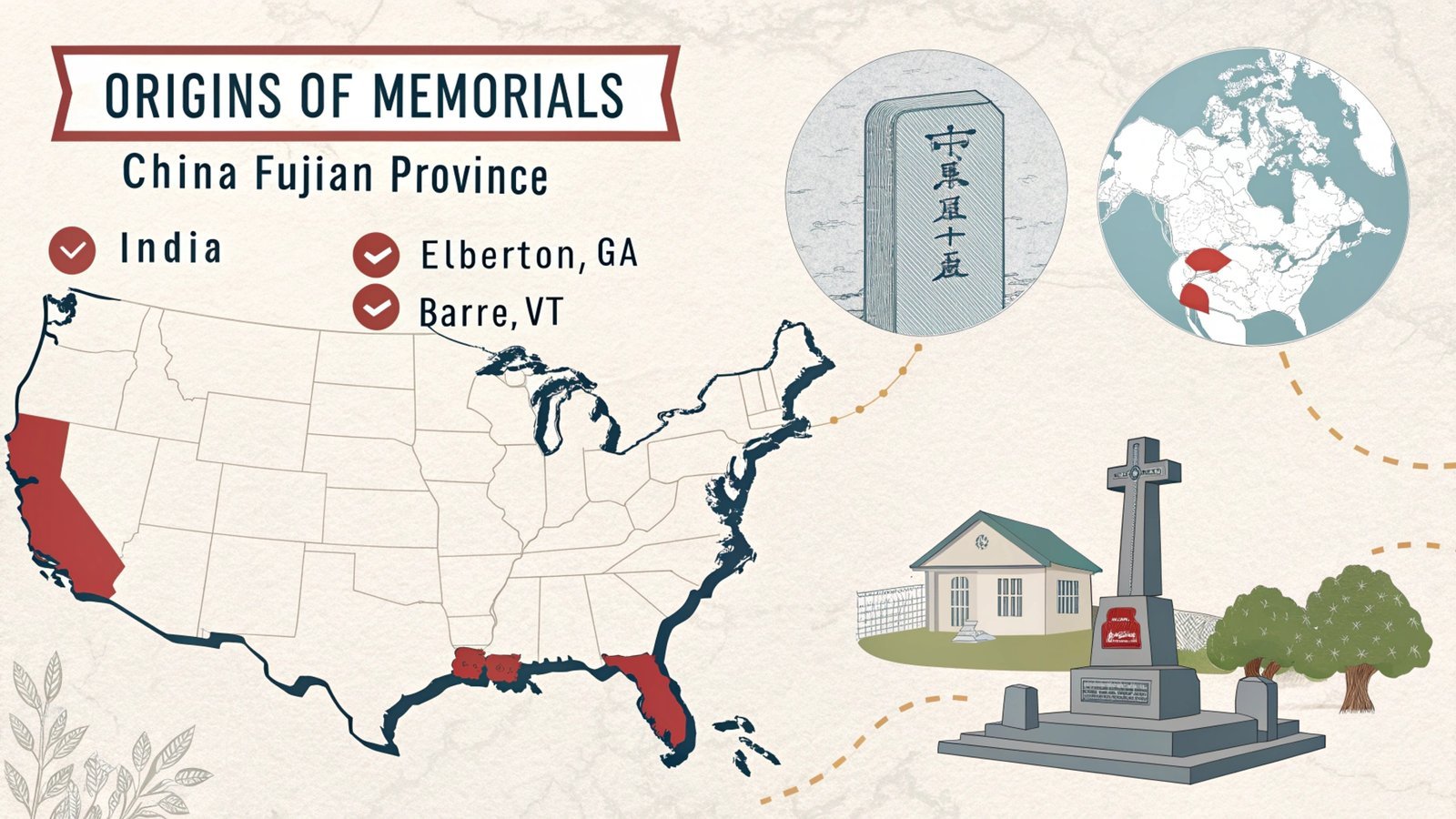

While headstones are made worldwide, major manufacturing centers include China (especially Fujian province), India, and specific regions in the US (like Elberton, GA, and Barre, VT). These areas often have abundant natural stone and specialized manufacturing infrastructure.

My journey in this business took me deep into the global supply chain, particularly China. The concentration of factories in certain areas is remarkable. It's usually tied directly to the availability of good quality stone.

Key Global Production Hubs:

- China (Fujian Province1): This region is a powerhouse. Why? Access to a vast range of domestic granites and marbles, plus efficient import of blocks from around the world (like India, Africa, Brazil). They have achieved incredible scale. Factories there handle everything:

- Large Cut: Slicing huge quarry blocks into manageable slabs.

- Large Grinding/Polishing: Automated lines for polishing slab surfaces.

- Hand-Pulled Cuts: Skilled workers shaping the stone.

- Hand-Carving: Intricate details added by artisans.

- Water Grinding: Finer polishing techniques.

- Shadow Carving: Highly detailed laser or impact etching, often for portraits.

- Sandblasting: Standard method for lettering and simpler designs.

The sheer variety of stone types and processing capabilities available is a major reason many businesses source from China.

- India: Another major exporter, known for specific granite colors like Black Galaxy and Vizag Blue. Similar manufacturing capabilities exist, often at competitive prices.

- United States: Historic centers like Elberton, Georgia ("Granite Capital of the World") and Barre, Vermont (known for high-quality grey granite) still have significant quarrying and manufacturing operations. They often focus on North American market demands and specific stone types.

- Other Regions: Brazil, South Africa, and parts of Europe also have notable stone industries supplying the monument trade.

Knowing these hubs helps understand potential differences in cost, logistics (shipping times, costs), stone variety, and sometimes even stylistic specialties. For someone like Sarah, understanding if her supplier sources from Georgia, Fujian, or India can inform expectations about delivery timelines and material options.

Who Actually Makes the Gravestones?

It seems simple, but the journey from a chunk of rock to a finished memorial involves many hands. Not understanding this process can make it hard to troubleshoot issues or ensure quality control along the way.

Gravestones are made through a multi-step process involving quarry workers, factory technicians (sawyers, polishers, shapers), designers, skilled artisans (carvers, etchers, sandblasters), and finally, installers. Different companies might handle different stages.

Having been inside the factories and managed the trade logistics, I can tell you it's a fascinating blend of heavy industry and detailed craftsmanship. It’s not usually just one "maker."

The Journey of a Gravestone:

- Quarrying: It starts deep in the earth. Workers extract large blocks of granite or other stone using specialized equipment. The quality of the block impacts the final product.

- Factory Processing (Manufacturing): The blocks go to a factory (like those concentrated in Fujian I mentioned). Here:

- Giant saws cut blocks into slabs of specific thickness (Large Cut).

- Slabs are polished using automated machinery or hand tools (Large Grinding, Water Grinding).

- Machines or skilled workers cut the slabs into the basic headstone shape (Hand-Pulled Cuts). Edges might be profiled or rounded.

- Design & Lettering: This might happen at the same factory or, more commonly, at a separate monument retailer/builder facility.

- A designer creates a layout proof (often digital).

- Once approved (remember that crucial family sign-off!), a stencil is created.

- The stencil is applied to the stone, and lettering/designs are typically sandblasted.

- Detailed work like hand carving or shadow etching is done by specialists.

- Finishing & Quality Control: The stone is cleaned, inspected for flaws, and prepared for shipping.

- Shipping & Logistics: Transport from manufacturer to wholesaler/retailer, then potentially to the funeral home or cemetery.

- Installation: A setting crew prepares the foundation at the cemetery and carefully places the monument.

Your funeral home might interact directly with a manufacturer (handling steps 1-4/5) or, more likely, with a monument retailer who manages steps 3, 5, and 6, sourcing the processed stone from a manufacturer. Knowing who controls which step helps you identify where potential issues might arise and who is responsible for quality at each stage.

Conclusion

Finding reliable gravestone manufacturers involves careful vetting, clear communication, and understanding the process. Focus on reputation, quality checks, and solid contracts to ensure families receive fitting tributes and protect your funeral home's name.

-

Understanding gravestone costs can help you budget better and make informed decisions about memorials.

-

Exploring key cost factors will provide insights into how to manage expenses effectively when choosing a gravestone.

-

Learning about supplier types and locations can help you find the best deals and services for gravestones.